| Availability: | |

|---|---|

| Quantity: | |

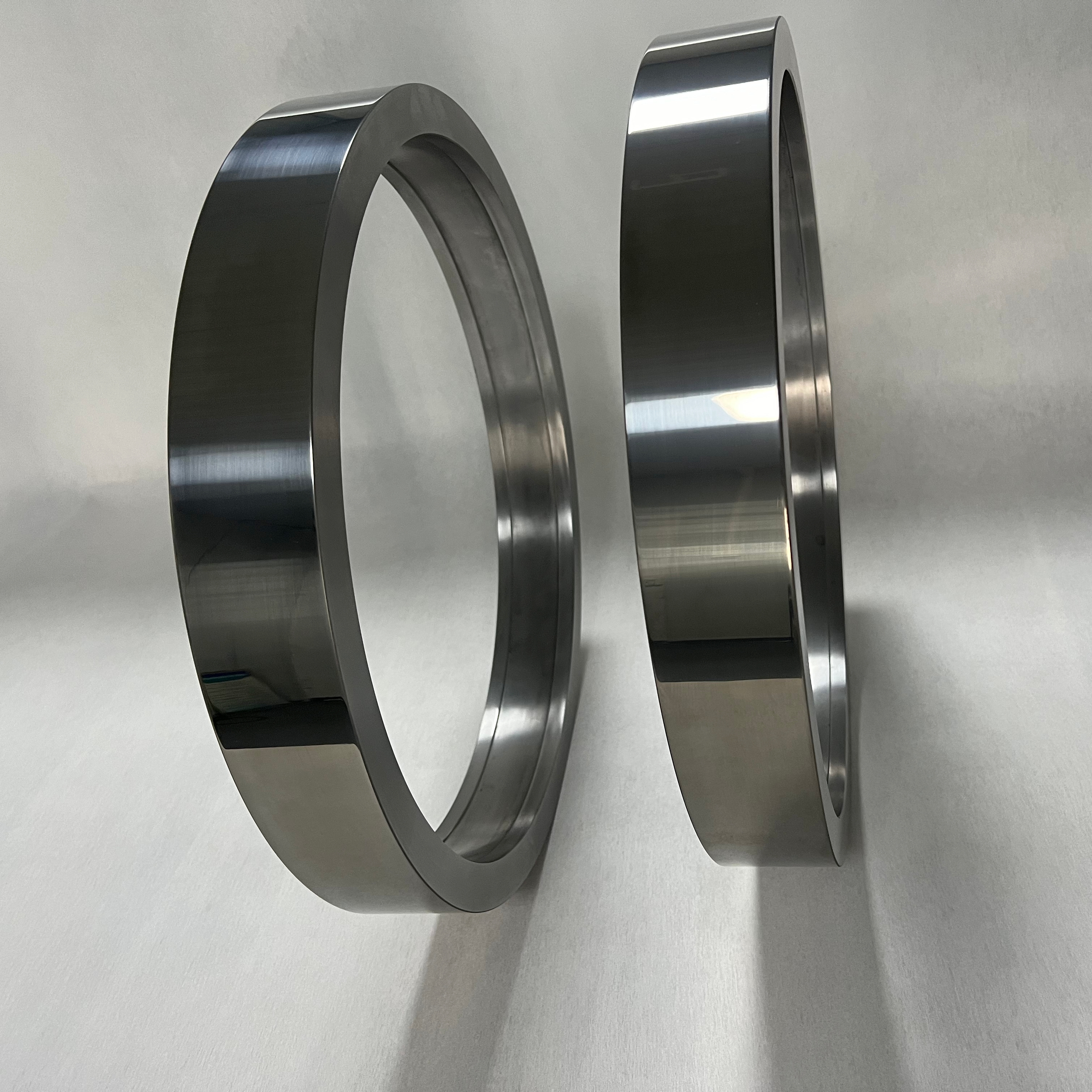

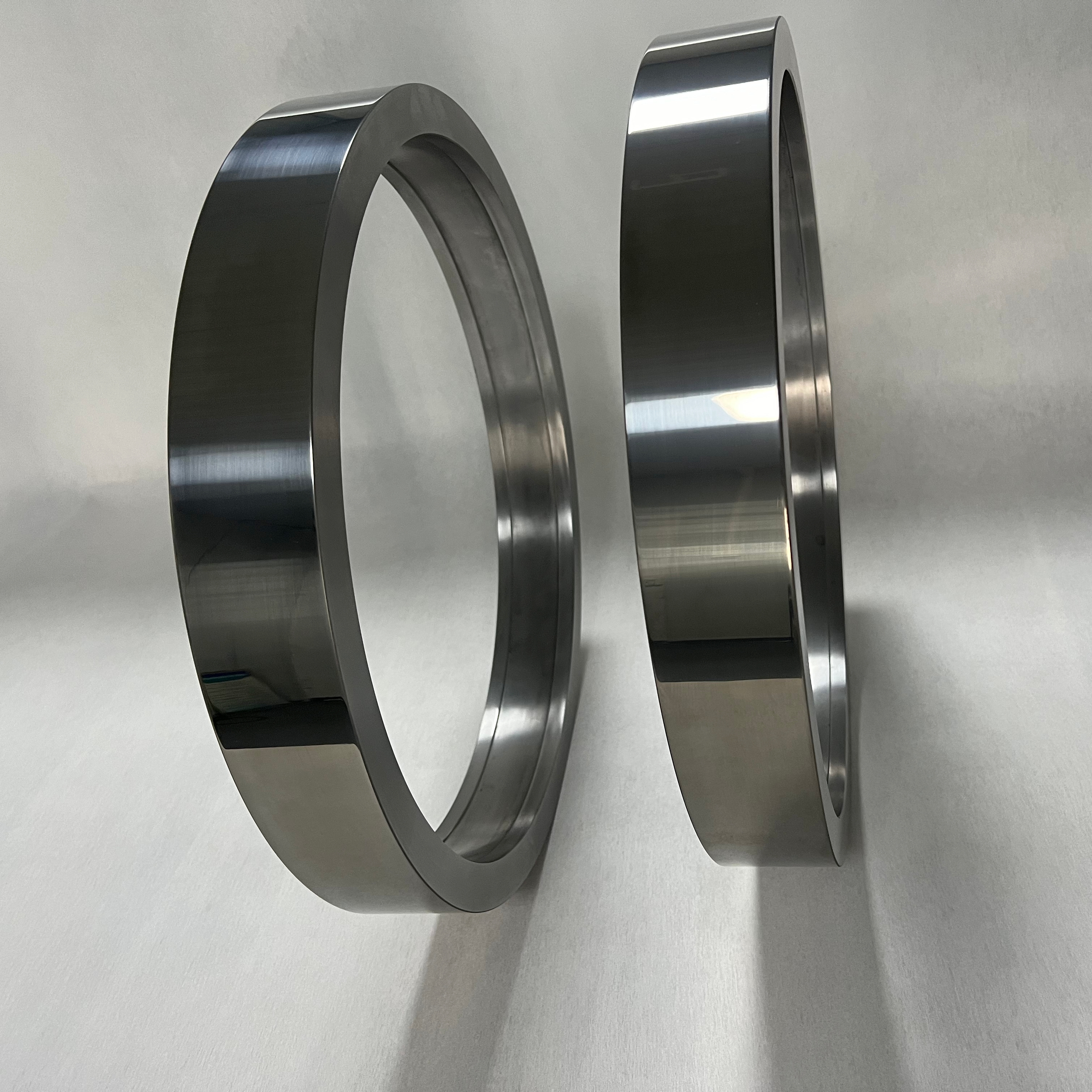

OD 450X ID 400X Width 60mm

SAHAM MACHINERY

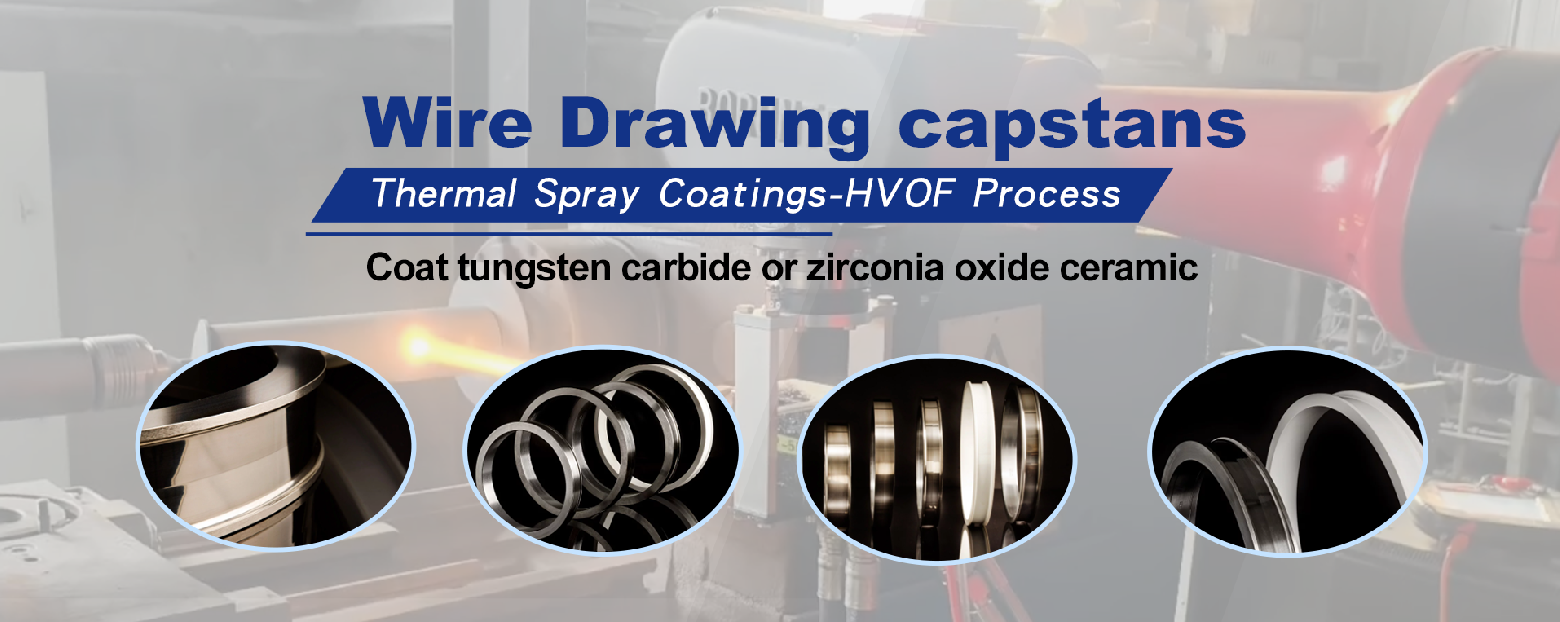

Our Spraying Equipement: HVOF spraying.

HVOF (High Velocity Oxygen Fuel) spraying is a thermal spray coating process that uses high-velocity, supersonic gas jets to deposit a coating onto a substrate. This process involves igniting a mixture of oxygen and fuel within a combustion chamber, creating a high-temperature, high-velocity stream that propels powdered material onto the surface to be coated. The resulting coating is known for its dense, low-porosity, and high-hardness characteristics.

Chemical composition | 9.5%C,10%Co,4%Cr, the rest W |

Finish | Tungsten Carbide Coated |

Precision | mirror polish |

Size | According To Technical Drawing |

Production process | Vacuum sintered |

Hardness | HRC65 |

Vickers-hardness | 1200~1400HV |

Coating Thickness | 0.25 mm for one side |

Product performance and application:

Excellent wear and corrosion resistance;

High bonding strength;

High impact toughness;

Excellent resistance to sliding wear;

More linking options and higher deposition rate;

Widely used in: various wear-resistant parts, valve seats, various rollers, compressor blades, etc.

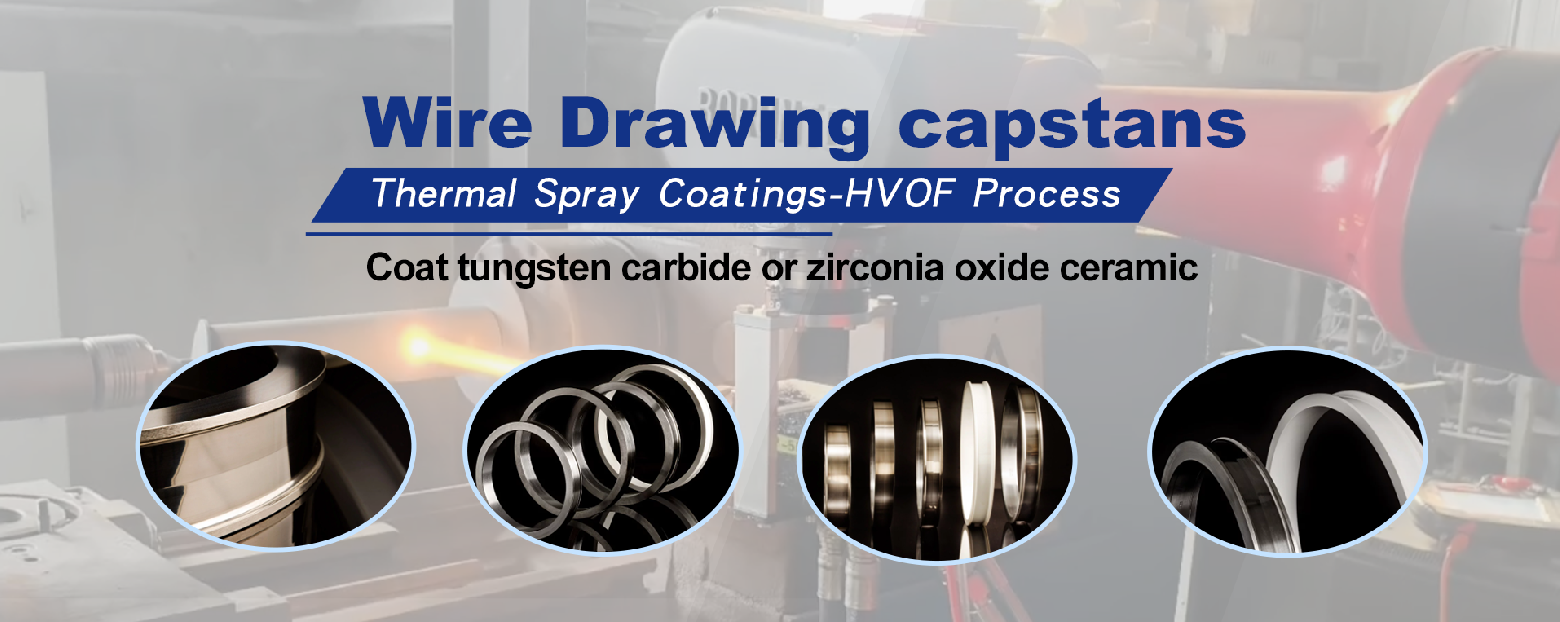

Our Spraying Equipement: HVOF spraying.

HVOF (High Velocity Oxygen Fuel) spraying is a thermal spray coating process that uses high-velocity, supersonic gas jets to deposit a coating onto a substrate. This process involves igniting a mixture of oxygen and fuel within a combustion chamber, creating a high-temperature, high-velocity stream that propels powdered material onto the surface to be coated. The resulting coating is known for its dense, low-porosity, and high-hardness characteristics.

Chemical composition | 9.5%C,10%Co,4%Cr, the rest W |

Finish | Tungsten Carbide Coated |

Precision | mirror polish |

Size | According To Technical Drawing |

Production process | Vacuum sintered |

Hardness | HRC65 |

Vickers-hardness | 1200~1400HV |

Coating Thickness | 0.25 mm for one side |

Product performance and application:

Excellent wear and corrosion resistance;

High bonding strength;

High impact toughness;

Excellent resistance to sliding wear;

More linking options and higher deposition rate;

Widely used in: various wear-resistant parts, valve seats, various rollers, compressor blades, etc.